11.28.1 G38.2 probe toward workpiece, stop on contact, signal error if failure.11.28 G38.x Straight Probe (CNC specific).11.27 G34: Calculate Delta Height from toolhead position (DELTA).11.25.2 G33: Delta Auto Calibration (Marlin 1.1.x - MK4duo).11.25.1 G33: Measure/List/Adjust Distortion Matrix (Repetier - Redeem).11.23.2 Probe and calculate in Repetier firmware.11.23.1 Probe and calculate in Reprapfirmware.11.23 G32: Probe Z and calculate Z plane.11.21 G31: Set or Report Current Probe status.11.19 G29.2: Set Z probe head offset calculated from toolhead position.11.17.5 G29 Mesh Bed Compensation (RepRapFirmware).11.17.4 G29 Auto Bed Leveling (Repetier-Firmware).

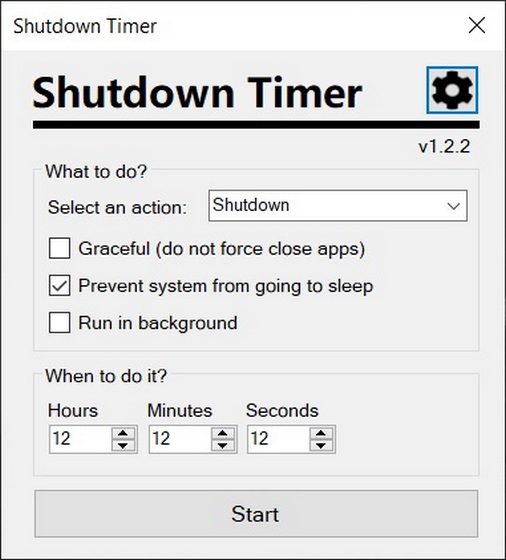

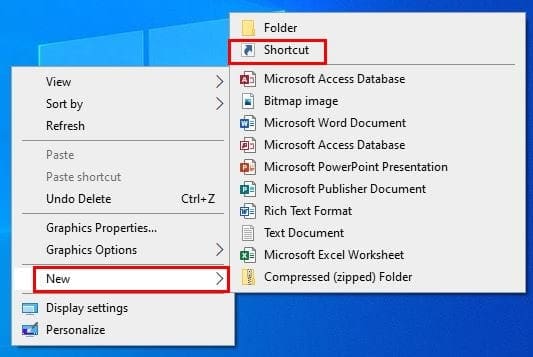

Cmd shutdown timer 1 hour manual#

11.17.3 G29 Manual Bed Leveling (Marlin - MK4duo).11.17.2 G29 Unified Bed Leveling (Marlin - MK4duo).11.17.1 G29 Auto Bed Leveling (Marlin - MK4duo).11.9 G17.19: Plane Selection (CNC specific).11.5 G10: Set tool Offset and/or workplace coordinates and/or tool temperatures.Note that the key date is appearance here, not date of implementation.

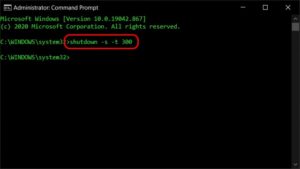

Cmd shutdown timer 1 hour code#

The rule which should be followed is that later appearances of a code on this page (later than the original use of a code), are deprecated and should be changed, unless there is a good technical reason (like the general G-Code standard) why a later instance should be preferred. Unfortunately human nature being what it is, the best procedures aren't always followed, so some multiple uses of the same code exist. The rule is: add your new code here, then implement it.

Nowhere in here should the same code be used for two different things there are always more numbers to use. This particular page is the master page for RepRap. This may be the best choice if you just need to run a few test lines while calibrating your printer.Īs many different firmwares exist and their developers tend to implement new features without discussing strategies or looking what others did before them, a lot of different sub-flavours for the 3D-Printer specific codes developed over the years. The final option is to just write the G-code yourself. Libraries like mecode give you precise control over the tool path, and thus are useful if you have a complex print that is not suitable for naive slicing. Another option for G-code generation is to use a lower level library like mecode. Slicers are the easiest way to go from a 3D model to a printed part, however the user sacrifices some flexibility when using them. These programs import a CAD model, slice it into layers, and output the G-code required to print each layer. One method would be to use a slicing program such as Slic3r, Skeinforge or Cura. There are a few different ways to prepare G-code for a printer. Codes for print head movements follow the NIST RS274NGC G-code standard, so RepRap firmwares are quite usable for CNC milling and similar applications as well. The main target is additive fabrication using FFF processes. This page tries to describe the flavour of G-codes that the RepRap firmwares use and how they work.

0 kommentar(er)

0 kommentar(er)